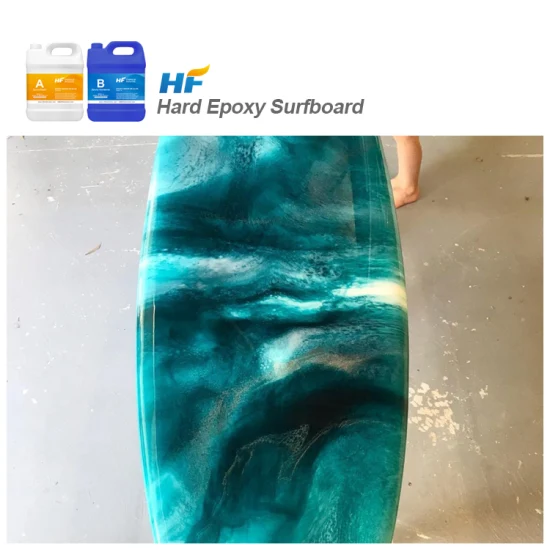

Direct Factory Wholesale Two Parts Ab Glue Crystal Clear Epoxy Resin for Surfboard Surface Coating

Basic Info

| Model NO. | HF2003-4 |

| Morphology | Water-Soluble |

| Application | Automobile, Fiber & Garment, Packing |

| Material | Epoxy |

| Classification | Room Curing |

| Main Agent Composition | Natural Polymer |

| Characteristic | Waterproof |

| Promoter Composition | Curing Agent |

| Composition | Organic Material |

| Color | Clear |

| Type | Double Components Adhesives |

| Mixing Ratio | 2:1 |

| Certificate | RoHS,Reach, PAHs, ASTM, En-71 |

| Life Time | Anti-Yellow at 5yrs+ |

| Grade | Food Grade FDA Approved |

| Voc | 100% Solids, Low Voc, Low Odor |

| Ripple | No Ripple, UV Resistant |

| Leveling | Self-Leveling and Extremely Durable |

| Transport Package | Barrel/ Carton/ Wooden Box |

| Specification | 1KG/5KG/20KG/50KG/ 200KG |

| Trademark | HF |

| Origin | Guangdong |

| HS Code | 3506912000 |

| Production Capacity | 5000000 Tons/Year |

Product Description

2:1 Fast Cure Yellow Reistance General Model for Surfboard Coating| Item (HF2003) | Epoxy Resin(A ) | Epoxy Hardener (B ) |

| Color | Transparent Liquid | Transparent Liquid |

| V[email protected]ºC(mpa.s) | 6000-10000 CPS | 250 CPS |

| Specific Gravity | 1.15 | 0.96 |

| Mixing Ratio(by weight) | 2 | 1 |

| Hardness(Shored) | 90 D | |

| Operation time(100g mixed glue ,25ºC) | 15 Minutes | |

| Hardening conditions | 25 ºC× 2-4H / 55 ºC× 1.5H | |

| Shelf Life | 12 Months | |

FeatureHF2003 High hardness, super yellow resistance , fast cure, two part epoxy resin system,widely used for carbon fiber products coating, fiber glass products coating, surfboard coating, lamp potting and mold filling, etc..It can be cured under normal temperature and low temperature, with the feature of high hardness, good flowing property, natural defoaming, fast curing

• High level of UV resistance, eliminating fading and yellowing •Ultra Clear ,Solvent Free• Mixes and blends with Rein Tints and Pigments• Excellent Adhesion to Polyester Filler Coats• Low Odor ,Excellent Clarity• Excellent resistance to yellowing ensure a lighter, stronger, more durable boardOperation Steps1.Weigh A and B glue according to the given weight ratio into the prepared cleaned container, fully mixed the mixture again the container wall by clockwise, place it along for 3 to 5 minutes, and then it can be used.2.Take the glue according to the usable time and dosage of mixture to avoid wasting. When the temperature is below 15 ºC, please heat A glue to 30 ºC first and then mix it to the B glue (A glue will be thicken in low temperature ); The glue must be sealed lid after use to avoid rejection caused by moisture absorption.3.When the relative humidity is higher than 85%, the surface of the cured mixture will absorb moisture in the air, and form a layer of white mist in the surface, so when the relative humidity is higher than 85%, is not suitable for room temperature curing, suggest to use the heat curing.Caution1. The operating environment should be ventilate and should keep away from fire. Closely sealed after use. 2. Avoid eye contact, in case of contact, wash with plenty of water and get medical attention immediately.3. If contact skin, wrap with clean cloth or paper, and wash it with water and soap.4. Keep away from children.5. Please take a trial before application to avoid usage mistake. Storage And Shelf Life1. Store at the tempestuous of 25°C or cool and dry place. Avoid from sunlight, high temperature or high humidity environment. 2. Use up as soon as possible when opened. It is strictly forbidden to expose to the air for a long time after it is opened to avoid affecting the quality of the products. The shelf life is six months in the room temperature of 25°C.

Packaging & Shipping

8oz, 16oz, 32oz, 1/2 Gallon, 1 Gallon Kit. 5KG, 25KG/DRUM for Epoxy resin AB glue.Bulk Business: 1150kg/IBC Drum, 23MT/20GP

Our Advantages

Free samples are available! Please contact us for more details and tell us what you need!