Multifunctional Sandwich Plate Epoxy Resin and Hardener Ab Adhesive

Overview Product Description MegaGlue 4003TG/BL is a high-performance solvent-free, slightly thixotropic two-component e

Basic Info

| Model NO. | MegaGlue 4003 |

| Material | Epoxy |

| Classification | Two Component |

| Main Agent Composition | Epoxy Resin |

| Characteristic | Waterproof |

| Promoter Composition | Curing Agent |

| Color | Yellow |

| Density g/cm3 | Resin:1.3; 0.05 Hardener: 1.23 |

| Pot Life /Min | 40-50 (60g) |

| Tack-Free Time /H | About 3 |

| Initial Adhesion Formation /H | 8-10 H / 90 Min |

| Curing | After 7 Days |

| Tensile Shear Strength / MPa | >20 (6 Series Aluminum/Aluminum) |

| Roller Peel Strength (N.mm/mm) | >60 |

| Hardness (Shore D) | 75 |

| Shelf Life | 12 Months |

| Transport Package | 20kg/Barrel; 36barrels/Pallet, 32 CTN/ Pallet |

| Specification | 20kg/barrel |

| Trademark | MegaGlue |

| Origin | Shanghai |

| Production Capacity | 20000/Month |

Product Description

MegaGlue 4003TG/BL is a high-performance solvent-free, slightly thixotropic two-component epoxy resin adhesive. It has excellent wettability to the substrate, has the characteristics of tensile strength, impact resistance, high peel strength and good toughness. In addition, the product also has the characteristics of low VOC, high thermal deformation temperature, and good resistance to humidity and heat aging.

Detailed Photos

| Product Detail | |

| Main Material | Epoxy Resin |

| Color | Resin: Blue Hardener: Brownish yellow |

| Appearance | Fluid |

| Component | Two component 2:1 |

| Density g/cm3 | Resin:1.31 ± 0.05 Hardener: 1.23 ± 0.05 |

| Pot Life /min | 40~50 (60g) |

| Tack-free time /h | About 3 |

| Initial adhesion formation /h | 8-10 h / 90 min(60ºC) |

| Curing | After 7 days |

| Tensile shear strength / MPa | ≥20(6 series aluminum / aluminum) ≥7(80ºC) |

| Roller peel strength (N.mm/mm) | >60 |

| Hardness (Shore D) | 75 |

| Shelf Life | 12 months |

| Features | MegaGlue 4003TG/BL is a high-performance solvent-free, slightly thixotropic two-component epoxy resin adhesive. It has excellent wettability to the substrate, has the characteristics of tensile strength, impact resistance, high peel strength and good toughness. In addition, the product also has the characteristics of low VOC, high thermal deformation temperature, and good resistance to humidity and heat aging. |

| Application | Mainly used to bond various sandwich composite panels (such as rail transit aluminum honeycomb floor panels, side wall panels, mid-top panels, phenolic resin panels, shelters, insulation panels and Hard PU and other composite boards) and various composite materials (such as carbon fiber, SMC, FRP, etc.). |

20KG/barrel ; 36barrels/Pallet, 32 ctn/ pallet

Store at room temperature, the recommended storage temperature is 10~30ºC. Avoid direct sunlight, high temperature, frost and humidity.12 months in the original sealed container.

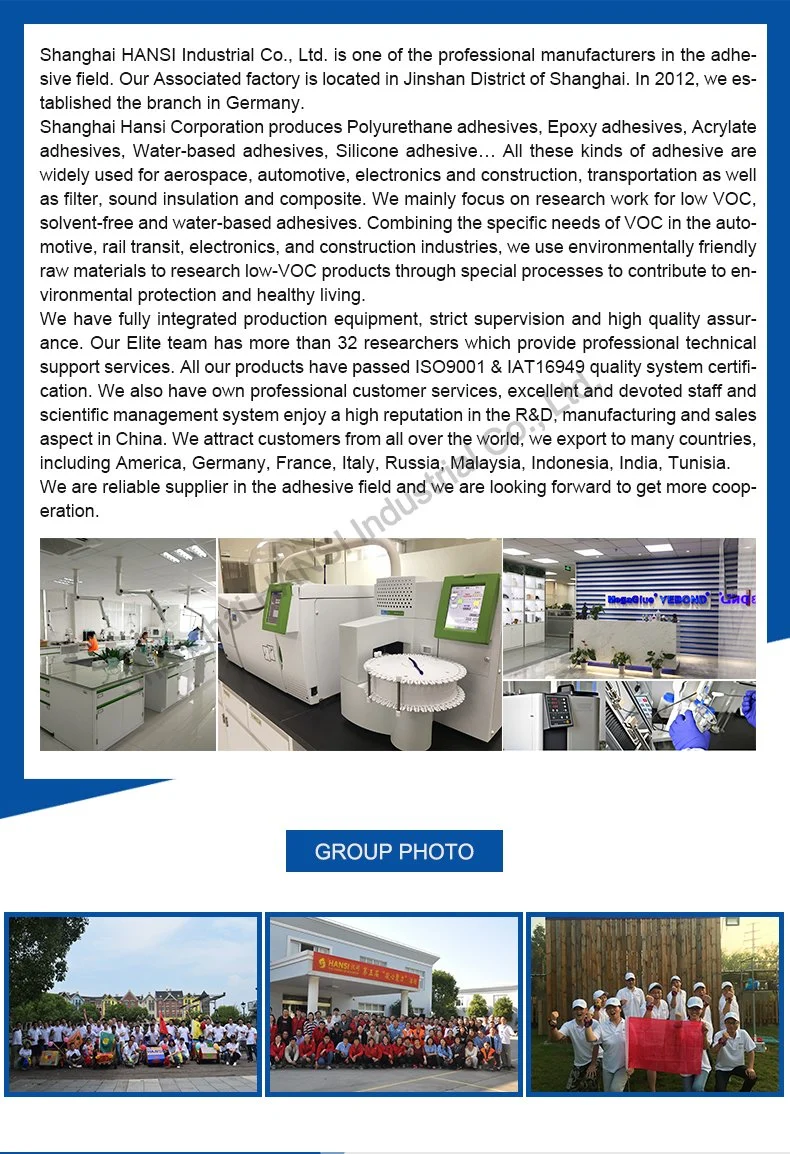

Company Profile

Send to us