Epoxy Resin Potting Sealant/Epoxy Resin Ab Glue / Clear Liquid Epoxy Resin Sealant for LED

Overview Epoxy Resin Potting Sealant/Epoxy Resin Ab Glue / Clear Liquid Epoxy Resin Sealant For Led Product Parameters F

Basic Info

| Model NO. | HF103-15 |

| CAS No. | 25068-38-6 |

| Formula | C15h16o2c2h7onc3h5ocl |

| EINECS | 231-072-3 |

| Bonding Function | Structural Adhesive |

| Morphology | Water-Soluble |

| Application | Construction, Fiber & Garment, LED Strip Light Potting |

| Material | Epoxy |

| Classification | Room Curing |

| Main Agent Composition | Natural Polymer |

| Characteristic | Waterproof |

| Promoter Composition | Curing Agent |

| Composition | Organic Material |

| Color | Clear |

| Type | Double Components Adhesives |

| Mixing Ratio | 1:1 |

| Certificate | RoHS,Reach, PAHs, ASTM |

| Life Time | Anti-Yellow at 5yrs+ |

| Grade | Food Grade Resin |

| Voc | Low Voc Low Odor |

| Ripple | No Ripple |

| Leveling | Self-Leveling and Extremely Durable |

| UV | UV Resistant |

| Solids | 100% Solids |

| Transport Package | Barrel/ Carton/ Wooden Box |

| Specification | 1KG/5KG/20KG/50KG/ 200KG |

| Trademark | HF |

| Origin | Guangdong |

| HS Code | 3506912000 |

| Production Capacity | 5000000 Tons/Year |

Product Description

Epoxy Resin Potting Sealant/Epoxy Resin Ab Glue / Clear Liquid Epoxy Resin Sealant For Led

Product Parameters

| Item (HF103) | Epoxy Resin(A ) | Epoxy Hardener (B ) |

| Color | Transparent Liquid | Transparent Liquid |

| [email protected]ºC(mpa.s) | 700-1500 CPS | 1200-1500 MAXCPS |

| Specific Gravity | 1.15 | 1.95 |

| Mix Ratio(by weight) | 1 | 1 |

| Hardness(Shored) | 40 D | |

| Operation time(100g mixed glue ,25ºC) | 30 Minutes(100g) | |

| Curing Time(25ºC) | 12-76 Hours | |

| Shelf Life | 12 Months | |

FeatureEpoxy resin HF103 can be cured under normal temperature and high temperature, with the feature of moderate viscosity, goodflowing property, natural defoaming, anti-yellow, high transparency, no ripple, bright in surface, good flexibility.Specially used for LED strips, and clear drop glue for some labels, ornaments and stickers.

* No Toxic Organic Compounds or Heavy Metals

* 100% Solids, Low VOC, Low odor,UV resistant

* Supersoft & Clear

*Not whitish, no bubbles

*Anti-yellow for at least five years

*Food grade FDA approved resin

Detailed Photos

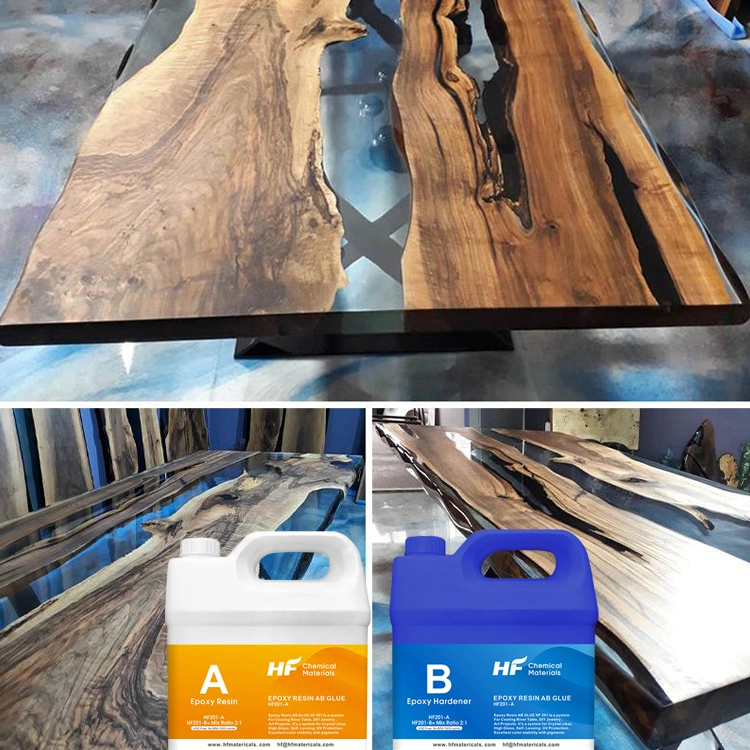

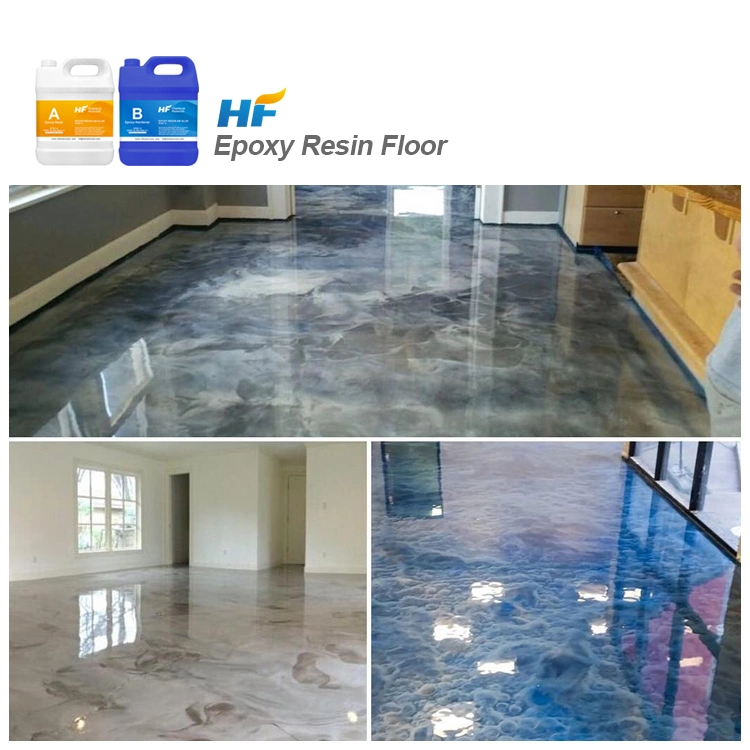

More Applications

Free samples are available! Please contact us for more details and tell us what you need!

Packaging & Shipping

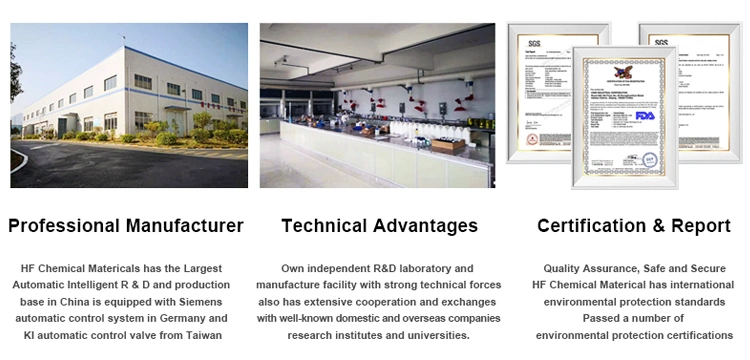

Our Advantages

Free samples are available! Please contact us for more details and tell us what you need!

Customers Feedback

FAQ

How to useStep 1: The ideal working temperature is around a constant 77°F. Best results can be obtained at constant temperatures between 70°F and 85°F, in a clean, dry, dust-free environment. Avoid working in high humidity. We recommend using this product on a leveled and flat work surface. Step 2: Measure product in accordance with your intended use. Prepare 2 parts Base Resin to 1 part Curing Agent by liquid volume.Pour the Curing Agent first and then the Base Resin into a clean, smooth-sided container large enough to hold all the liquid and allow room for mixing. Step 3: The material must be mixed thoroughly for at least 3 minutes. Be sure to scrape the container sides, bottom, and corners as you mix. Be careful not to whip excessive air into the mixture. If mixing a gallon, use a power mixer set to "hand speed." For smaller quantities, use stir sticks. Do not mix more than a gallon. Pour into a new, clean container and mix for an additional minute. Step 4: Pour the mixed resin onto the surface and distribute evenly with a squeegee or gloved hand. Continue to pour remaining material to achieve the desired thickness, allowing the resin to flow evenly over the project's sides. Resin can be poured up to 1/4" thick per pour. Step 5: Use a heat source such as a heat gun to remove any bubbles by adding a small amount of heat to the surrounding area. The bubble will rise to the surface and pop. Step 6: If you are going to make a second pour, the first pour should still be slightly sticky. Once the second pour is made, bubbles may once again need to be removed. Material will feel hard after 45-60 minutes, cure to the point of workability within 24 hours, but full cure and maximum hardness can require up to 7 days, depending upon the temperature.Free samples are available! Please contact us for more details and tell us what you need!Send to us